Technology Innovation Institute (TII), the applied research pillar of Abu Dhabi’s Advanced Technology Research Council (ATRC) today announced that its Directed Energy Research Centre (DERC) has become the first entity in the GCC region to operate a Laser-Matter Interaction Laboratory (LMI Lab) capability.

The LMI Laboratory is part of the Laser, Photonics, and Optoelectronics (LPO)Division, which investigates the physical processes involved in the interactions of a broad range of lasers with matter. In doing so, the division develops new methodologies in different fields, such as laser materials processing, plasma physics, nanotechnology, and non-linear optics.

The mobile laser laboratory provides unique opportunities to perform innovative and experimental testing in both indoor and outdoor environments. The laboratory offers critical infrastructures, service providers and research institutions in the UAE and the wider GCC region enhanced access to laser-matter interaction capabilities– a function that previously, was outsourced abroad.

The availability of the capabilities in the region also paves the way for a higher uptake of lasers in multiple applications across diverse industries.

Dr. Ray O. Johnson, CEO of Technology Innovation Institute (TII), said: “We are encouraged by the work accomplished by DERC’s researchers in getting this sophisticated lab operational in a very short time. At this fundamental research lab, we plan to investigate two closely-related topics –one is the interaction of matter with a strong laser field, i.e., at high power densities. The second is to study matter at very high energy densities, i.e., hot dense plasmas. The outcomes of such experiments will further enhance DERC’s and TII’s credibility as regional leaders in high-energy physics.”

Speaking on the breakthrough, Dr. Chaouki Kasmi, Chief Researcher, Directed Energy Research Centre (DERC), said: “The launch of the Laser-Matter Interaction Laboratory is a significant addition to DERC’s growing portfolio of cutting-edge technological solutions that are shaping our future. While established technology leaders including the USA, the UK, France, Germany, and many others already possess this tech solution, it is unique to the GCC region and much like our electromagnetic compatibility labs, is expected to have wide-ranging implications in scientific testing as well as commercial and industrial applications.”

DERCand our partners are working on innovations in domains such as laser materials processing- welding, cutting, drilling, sintering, hardening, cladding, surface treatment, plasma technologies, electromagnetic pulse generation, plasma waveguiding, remote sensing, laser communication, and nanomaterials.

Dr Kasmi added: “Lasers are used in an extraordinarily wide range of applications. One area that is increasingly important is the manufacturing sector, where the level of precision at which a laser can operate is far greater than that of the equivalent physical tool. With this laboratory, we will be able to support the manufacturing sector – among the priority industries for countries in the region. Apart from this, the lab will enable new scientific research and development capabilities and support other industrial applications – such as the next generation of telecommunication technologies.”

DERC’s future capabilities will comprise an ISO class 7 cleanroom and a mobile laser laboratory with environment simulation chambers (environmental, turbulences, and vibration) and different laser systems, such as multi-kilowatt lasers in continuous wave (CW) and multi-terawatt lasers (TW) in pulsed mode.

In addition, the LMI Laboratory will further theoretical and experimental advances in different fields that rely on light-matter interactions, including atomic, molecular and optical physics, photonics, chemistry, and optoelectronics, among others.

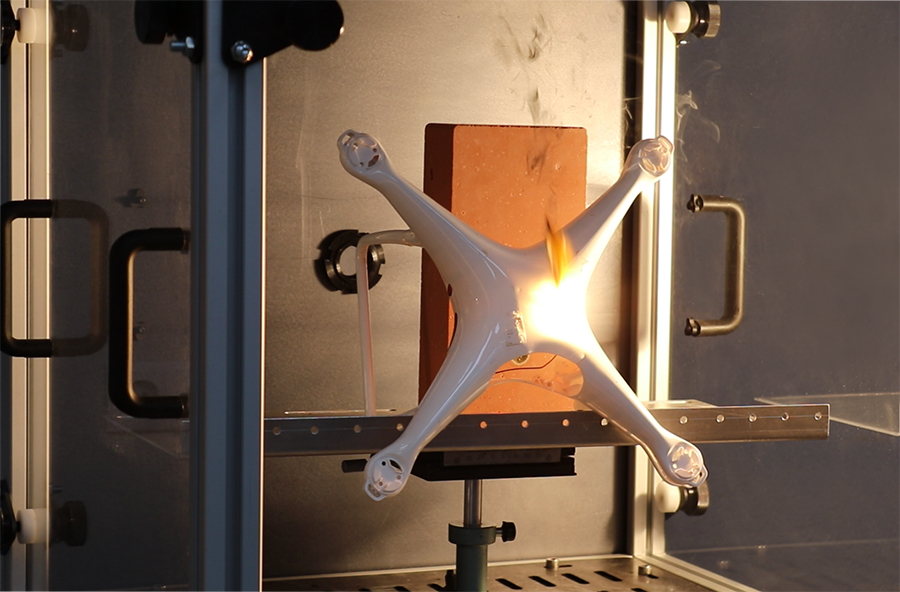

The laboratory is set to study the heating, melting, and evaporation mechanisms induced in laser-matter interaction, according to a broad range of laser parameters on various solid materials. The investigations at the laboratory will be helpful inoptimising the process parameters in laser materials processing to facilitate products of the desired quality.

Furthermore, high-speed imaging and spectroscopy research can lead to the development of low-cost, compact online monitoring tools for quality control in production, thereby enabling cost and time savings in the post-mortem analysis for quality assurance. To observe the fast phenomena taking place during the laser-materials interaction process, the lab will also leverage several diagnostics tools such as high-speed camera, streak camera, picosecond gated intensified charge coupled device camera and spectrometers.

Another key capability at the laboratory will be thermal blooming, caused due to the nonlinear interaction of the high-power laser beam with atmosphere in which certain molecules and particulates absorb a fraction of the laser radiation. To study this effect, the team at DERC will deploy outdoor laser sources and different sensors to investigate the physical processes involved in the interaction of different lasers (CW & pulsed) in the GCC environment.